AGITATORI D’ARIA

“Agitatori d’aria” is an Italian definition (meaning literally “air agitators” or “air shakers”) used by the company Ercole Marelli & C. to define the “luxury” models of fan used for domestic environments.

In 1896, imported from the United States, the first electrical “agitatori d’aria” appeared in Italy. Ercole Marelli realised the commercial potential and started their own production of fans.

The first models were very similar to the American ones but were quickly followed by others of different shapes but more graceful and elegant yet still at a reasonable price. This decision was a great success and, by the end of the 1920s, production reached over 150,000 fans a year exported all over the world.

In 1898 Marelli moved to a new workshop in via Farini no. 21 in Milan and the production and sale of fans continued to grow and a uniform “first series” of models began to take shape. The manufacturing plant is illustrated in their 1898/99 brochure.

In the 1898 catalogue specific for “fans and agitators of all kinds for table, wall and ceiling” was published. This catalogue provided the first images (as far as we know) of the Phase 0 Marelli models including the “Auretta”, “Eolo“, “Buffa“ and “Ciclone“.

[For more info see the post “History“ and “Catalogs“]

The “standard” production of fans was characterized by a cast iron body, painted in black (Japanned) together with blades, cage, oilers etc. in brass (with different finishes: nickel-plated, oxidized, etc.). Marelli’s core strategy was that, for domestic use, fans must be simple, light, portable and lastly, affordable.

THE TYPES

The models produced by the company totalled 76 [1], differing by type (table, floor, ceiling, etc) and by size (usually referred to by blade diameter). Each model could be made with a brush or an induction motor (the latter being a Marelli-Zanoncelli patent).

Each model could operate at:

– “Corrente Continua” (CC) / Direct Current (DC) with 6 different voltages;

– “Corrente Alternata” (CA) / Alternating Current (AC) with 6 different voltages and at 8 different frequencies “Hz” (from 25 Hz to 133 Hz).

So each model had 54 variants and for all 76 models this totalled 4104 “types”. To this number of “standard” models one must also add the “special” models that could be requested these being different paint options or the nature of the brass components (cage, oilers, etc) that could be supplied in oxidized brass, nickel-plated, gilding, etc.

Ercole Marelli fans can be broadly grouped as domestic fans (“agitatori d’aria“) or as industrial fans with the two types being built at different factory departments.

• The “AGITATORI D’ARIA” included:

– Table fans (da tavolo): fixed (fisso), inclinable (inclinabili) and oscillating (oscillanti).

– Bracket fans: being table fans that could be attached to a wall using a universal joint or wall bracket (referred to as the “Raccordo“)

– Floor standing fans (da terra/a piantana), often referred to as column fans (colonna)

– Ceiling fans (da soffitto, da plafone), further divided into:

A. Revolving: with large blades (modelli girevoli, modelli piccoli o modelli a grandi pale). This included the more traditional examples of ceiling fans. The motor head is fixed and carried large wooden or metal blades. Speed was controlled by a wall mounted rheostat. Models included:

(A1) – attached directly to the ceiling (termed Saloon (Salone) fans), with 3 aluminium blades and carrying no shaft e.g., the Falco (80 cm), Nibbio (90 cm) and Salone (80 or 90 cm).

(A2) – those having a long shaft, e.g., Tempesta (60, 80 or 90 cm), Burrasca (80, 90 or 110 cm), Brezza (135 cm), Breva (135 cm), Vortice (150cm), Maestralino (120, 135 or 142 cm), Maestrale (150 or 210 cm), Aliseino (135 cm), Aliseo (150 cm), Aliseino (142 cm) Condor (90 cm) Astra and Airone (50 cm) and termed “Tipo a Grandi Pale” (large blades). Each model had the option of 2, 3 or 4 wooden blades and some, such as the Breva had the option of also including lighting.

B. Girevoli: fans hung from the ceiling by a long shaft and carryied either a ball head/brushed or pancake/induction motor that rotated 360 degrees and could be inclined to alter the angle, models included the Ciclone (30 cm), Turbine (40 cm), G.30 (30 cm) and G.40 (40 cm). Interestingly, studies at the company had shown that a cyclical delivery was preferable to a continuous current of air.

– Cabin fans: suitable for rooms with low ceilings (cabina or plafone). These models carried protective cages and examples included the Libico (30 cm), Monsone (30 cm), Tivano (40 cm) and Egizio (40 cm) which were attached to the ceiling (soffitto) and the Cabina A (25 cm), Cabina B (30 cm) and Cabina C (40 cm) that could be attached to the wall (parete) or ceiling (soffitto).

– Aspirator fans (aspiratori elicoidali): attached to a grill and embedded in a wall or window, e.g., the models, Zeffiretto (25 cm), Tormenta (40 cm), Uragano (30 cm), Artico (25 cm), Siderale (40 cm) and Polare (30 cm). These fans provided a basic form of room ventilation or for exhausting air, dust and fumes from the workplace.

– Small motors (referred to as “piccoli motori” or little motors) that were adapted for use in polishing, buffing and other small-scale industrial tasks. Initially, the same “agitatori d’aria” heads were used but in 1920 this was abandoned in favor of a specific series of motors. Marelli also patented a small motor, with traction ignition, for pedal-powered sewing machines.

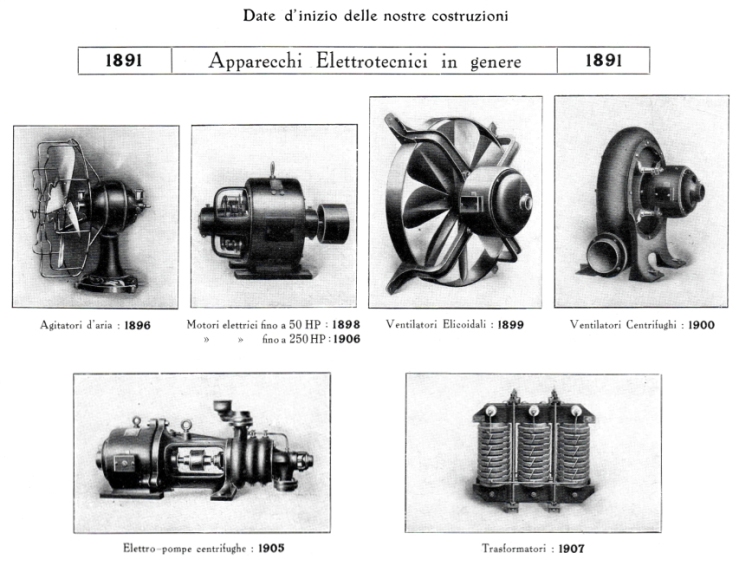

• INDUSTRIAL FANS including:

– Centrifugal fans (ventilatori centrifughi): fans capable of delivering air at high pressure and used for a variety of purposes such as in food ovens and forges, etc. There were several classes of these fans. First, the “Fucina” made in cast iron that could produce small quantities of air at high pressures sufficient to operate forges and pneumatic equipment, etc., and second, the “Marina” an intermediate series of fans that produced medium quantities of air at medium pressure and used for ships, for example they were used by the “Royal Italian Navy”). Finally, the “Lamiera” fans that were used in sheet steel production (producing large quantities of air at low pressure).

– Helicoidal fans (ventilatori elicoidali): for weak pressures, that were directly coupled with electric motors (for voltages up to 500 V). They were used for renewing fresh air or to remove smoke, dust, odors etc. from rooms or workplaces (e.g., the Grecale fan).

[1] in 1911 – taken from the publication published by the company itself in 1911 and entitled “Ercole Marelli, Pel XX Anniversario“.